Making Spring Loaded Go-Bars

At our annual luthiers camp on Kauai in 2019, fellow luthier Brad Donaldson inspired me to make these spring loaded go-bars to replace the oak stick bars I have used for almost 40 years.Go-bars are used to glue the bracing in place and some even use them for gluing on tops and backs.I thought I'd give them a try and this is my take on Brad's suggestion. Lots of luthiers make these, and I'm sure there are many ways to do it. This not meant to be a complete tutorial, just a starting point for ideas should you decide to try making some. These bars do require your decks to be standardized if you have more than 1. My bars are designed to have an adjustable height by adding a 2nd short piece of wood dowel to the top if needed, as per Brad's design.

The idea behind this project was to eliminate this!

I made my bars out of 1/2" CPVC tubing and 7/16" wood dowels. Here are the parts. The CPVC, wood dowel, a compression spring, a couple of pieces of brass rod which go though the CPVC to act as stops, a piece of 1/8" cork, and a piece of nylon uke string. If you are making these, keep in mind that wood dowel is far more expensive than CPVC and designing to make your longest lengths out of the tubing will save you a lot. These clamps cost me $2.53 each in materials.

The hard part of this project is coming up with the right lengths to cut the tubing and the dowel into and finding springs you want to use. Brad used an assortment of springs that he found in a combo pack and I used a uniform size, but I had to go all three Ace Hardware stores in the area to find the quantity I wanted. The lengths to cut things into depends on the height of your go-bar deck, and the travel in your compression spring. My compression springs have about 3/4" of travel.

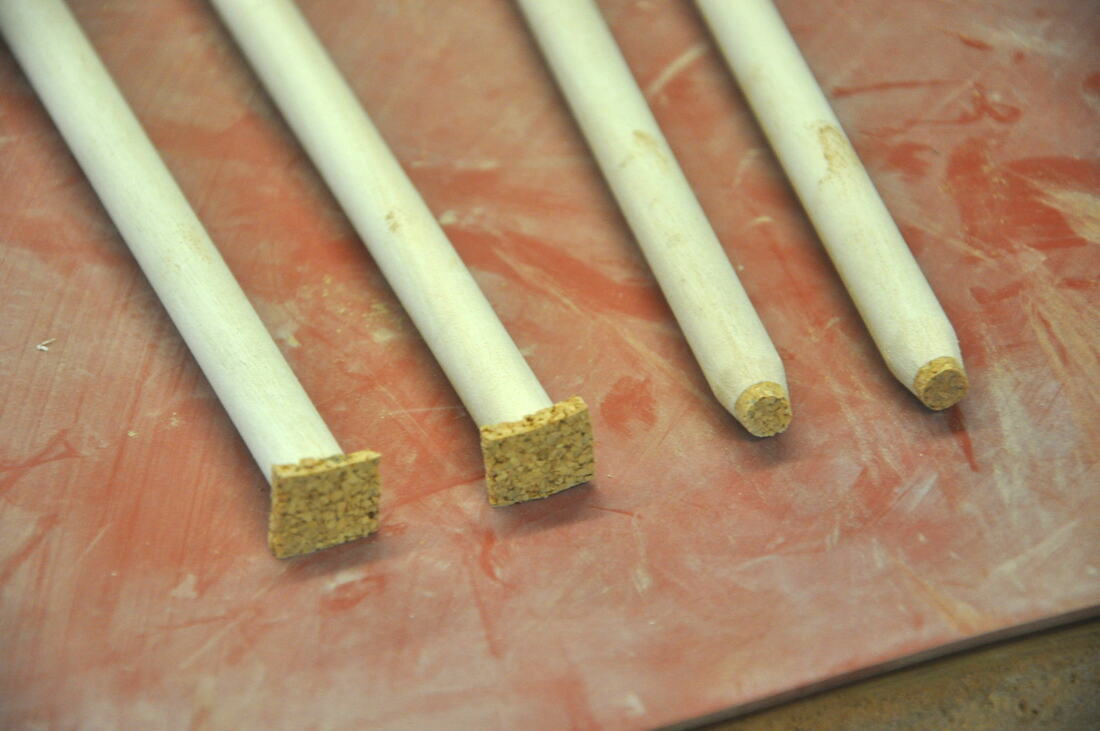

I glued cork onto the dowel ends to limit denting of the wood being glued. I've always done this on my sticks and the cork lasts for years. I put a generous amount of glue on the dowel end grain and on the cork. Prop the bars up in your deck to hold the cork on til' it drys. When it's dry, take the bars to your sander and turn them down to a smaller dimeter to help with glue clean-up.

This next photo shows uke string threaded through the CPVC and dowel to prevent the dowel and spring from dropping out. High tech stuff! A small diameter string, like .025 or so, worked best for me.

This is what I love about go-bar decks. You can stack them to the ceiling and they take up almost no space. The bars won't come loose, even if you leave them for a month. This way of gluing bracing fits my schedule the best. My next project is to try and make some lighter weight laminations in combination with carbon fiber to make the materials in my guitar decks lighter. Uke decks are light, my 30+ year old particle board guitar decks are way too heavy!