Radiusing Braces with a Handplane

Here is an idea for making radiused bracing with a handplane. I've seen a few versions of this on the net, but this jig is a little different. Everyone who makes this jig will come up with a slightly different take on it. If you find a better way, please share it with me.

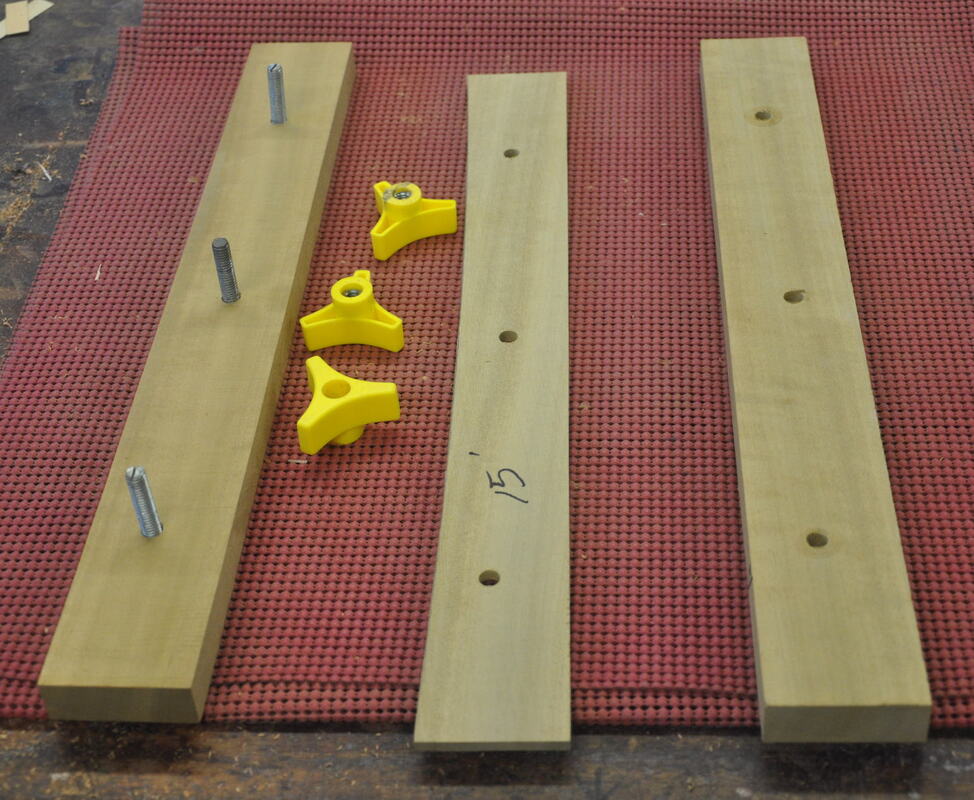

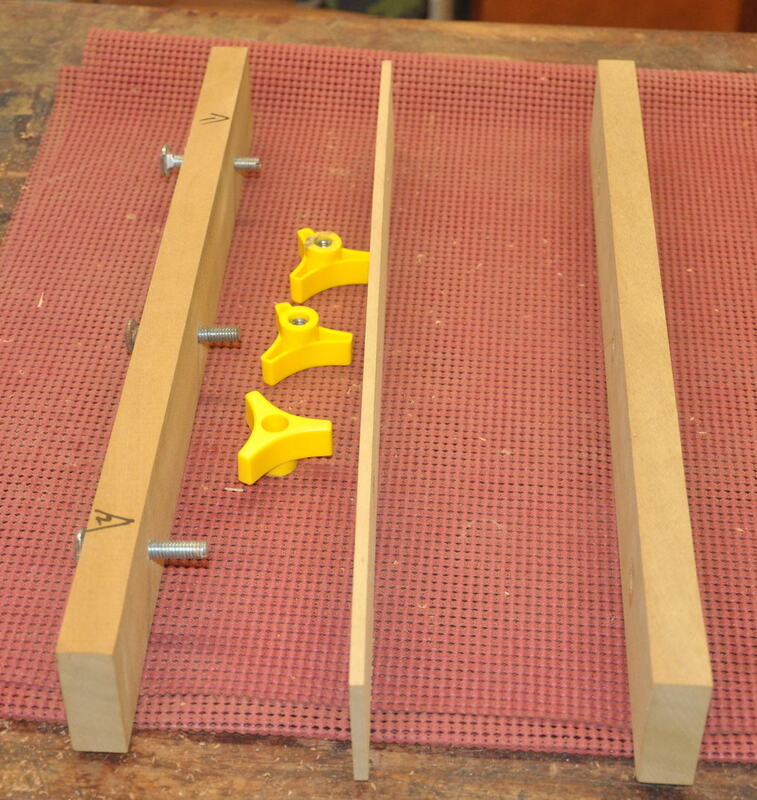

The parts. Length is dependent on the longest brace you want to shape. Best material to use is a straight, stable hardwood.

The parts. Length is dependent on the longest brace you want to shape. Best material to use is a straight, stable hardwood.

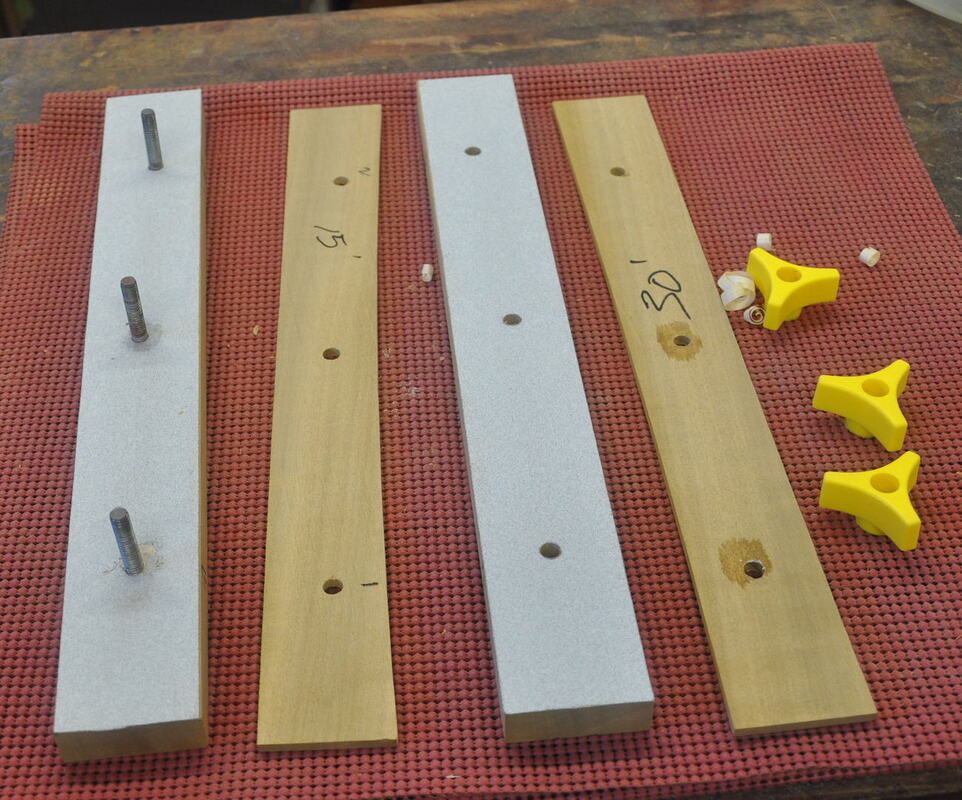

The center template is concave and shaped to the radius you want and needs to be slightly thinner than your brace. My template for a 6mm thick brace is about 5.2mm thick.

After cutting out the basic pieces I apply sticky back sandpaper to the outside holding pieces. This photo shows a 15' and a 30' radius template. You can make as many templates as you want and use them in the same holding jig.

The bolts I used were carriage bolts. I've seen builders use regular nuts instead of the plastic knobs I used. There are many other options you could use.

1st photo is a 6mm spruce brace, squared top and bottom. The 2nd photo is that brace being pressed down in the center with a clamp until it touches the curved template. The shape of the clamped brace will be concave on the exposed edge.

Tighten the holding knobs very tight. Then need to keep the brace from returning to straight. Then lay the jig over on it's side. The carriage bolt heads are countersunk to allow the jig to lay flat. The exposed edge of the brace will be concave. You can use a block plane or something longer (better longer) to plane the concave surface to a straight edge.

When you have completed this process, you'll find that the edge you've just planed straight will flex into a curve matching the radius of your curved caul when released from the jig. I like the fact that I can now make a radiused brace easily without having to use a sander and create more dust in my shop. Getting the radius caul to the right shape is the difficult part of this jig. I've found that it seems best to add a degree or 2 to the template radius. If your radius center piece is too deep in the center when the brace is compressed, just add a thin spruce shim under it. Results will be the same.

This type of jig makes cylindrical shaped curves. Dishes are actually spherical curves, but I've had no issues with that. I've used cylindrical curved braces for a long time with no issues. I supposed you could touch up the curved brace in a dish if desired.

Enjoy your building! Feedback to [email protected]

This type of jig makes cylindrical shaped curves. Dishes are actually spherical curves, but I've had no issues with that. I've used cylindrical curved braces for a long time with no issues. I supposed you could touch up the curved brace in a dish if desired.

Enjoy your building! Feedback to [email protected]